Why Choose Shigiya?

- Over 100 Years of Japanese quality!

- Dedicated machine tool style discipline, “All we do is grind”

- Knowledgeable and accessible service & parts team

- Bilingual in English, Japanese and Spanish

- Service and parts are available to the Continental U.S., Canada, and Mexico

- Machines are field option ready

- High stability ribbed cast iron construction

- Extended longitudinal ways eliminate overhang to provide long effective life of built in accuracy

- Symmetrical box design

- Our machines go through rigorous quality inspections at factory

- Our designs minimize thermal expansion and improve load bearing capacity

- Precision hand scraped surfaces

- Maximum built-in long-life accuracy

- Proven machinery, built to last

Shigiya Original CNC Conversational Software

Shigiya original CNC conversational software was developed to enable fast and easy programming. Operators simply input three items of information for each diameter of grinding and processing automatically begins. Grinding options include plunge grinding, taper traverse grinding, traverse grinding or oscillation grinding.

- High Accuracy and Efficiency

- Fanuc backed control

- Perfect for transitioning from manual to CNC equipment

- Not complicated

- Quick interaction to shorten cycle times

- Fast set-up

- Easy programming

- Automatic grinding conditions

- New wheel dressing cycles

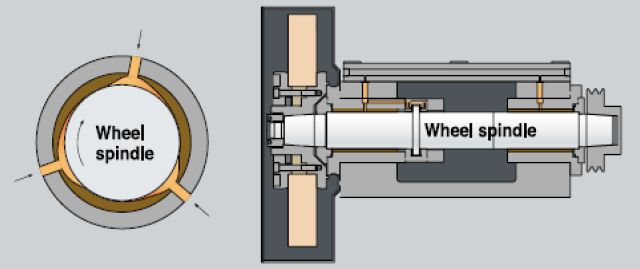

Wheel Spindle Design:

- Non-Concentric Hydrodynamic Bearing Construction

- Uses hydrodynamics to secure the optimum wedge angle

- High rotational rigidity and cool running for high accuracy and durability

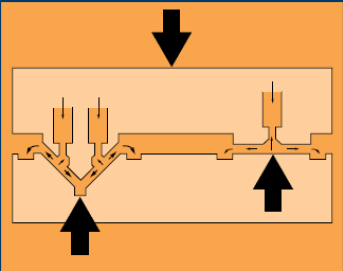

Automatic Lubrication System:

- Highly rugged feed mechanism to guarantee precision grinding

- The wheel head and table-feed sliding surfaces have wide, V-flat guiding surfaces that have sufficient rigidity and load capacity